Martinsons is a wood construction systems provider specialised in using glued laminated timber (glulam) and cross-laminated timber (CLT). The company has a long history in both wood processing and wood construction. It was founded in the 1920s as a mobile sawmill that evolved into a stationary sawmill in the 1940s. In 1965, glulam production began at the sawmill, and five years later, Martinson built the first specialised glulam factory. Martinsons introduced its first building system in wood in 2003 and opened a wood construction system factory in 2017. All wood processing and construction system units have been owned by the Martinson family for four whole generations. In July 2020, Martinsons was acquired by the Holmen Group who integrated all wood processing units into its operations. Since then, Martinsons has become an independent SME focused on the wood construction system business.

Martinson’s construction systems in glulam and CLT have been developed to make optimal use of the material’s properties. To that end, the systems are designed to be flexible and accommodate a wide range of different uses as well as alterations and improvements over time. The construction systems combine low weight with great load-bearing capacity and the possibility of having large spans in buildings. Built in wood, the systems also provide an environmentally sustainable option to building in concrete or steel. These properties make Martinsons wood construction systems attractive for building a wide range of different buildings, including sports halls, business premises, agricultural buildings, apartment buildings, office buildings and bridges.

During the last couple of years, regulatory shifts and a growing interest in sustainable construction has led to a substantial increase in customers that want to build tall buildings in wood. Martinsons is now seeking to leverage its experience and expertise in glulam and CLT to capture a share of this market and has recently, for example, constructed the wooden framework for Sara culture house in Skellefteå that by being 80 meters and 20 stories high is one of the largest wood buildings in the world.

The important need to be solved

Specifically, Martinsons is experiencing the following challenges:

- While Martinsons is a pioneer and market leader in wood construction, new wood construction entrants as well as established steel and concrete actors are threatening its position.

- Wood construction knowledge and expertise is distributed across paper documents and the heads and hands of individual employees in the organisation

- High buildings in wood are a relatively new phenomena and every project involves dealing with unknown factors and risks. Due to these uncertainties, it is difficult to accurately calculate bids and ensure that projects ultimately will be profitable.

- Constructing high buildings in wood infers an increase in complexity both in terms of ensuring the structural integrity of buildings and coordinating between different specialised construction partners.

- Each construction project gathers a wide range of different companies that often lack or use their own specialised systems for project collaboration. This creates challenges in terms of data exchange.

- Martinsons has a high willingness to adopt and experiment with new digital technologies, yet experience challenges with leveraging their potential in full. Digital initiatives sometimes run for limited periods and fail to assimilate fully into the organisation and other implementations have tended to result in silo-building and low interoperability.

Approach for solution

The challenges experienced by Martinsons were addressed by students at the IT-Management master program at Umeå University. In total, 24 students worked in 5 smaller groups supervised by experienced teachers and researchers to develop suggestions for how Martinsons could address its challenges by leveraging digital technology. Specifically, the students were tasked with developing a research-grounded long-term digital transformation roadmap consisting of distinct developmental steps that Martinsons should take.

The work for each group involved analysing the status quo at Martinsons, identifying challenges, opportunities, and conditions within and outside the company that were most likely to trigger, fuel or in other important ways influence a digital transformation process. Based on their analysis of the status quo, each group was to suggest a long-term digital vision that Martinsons should strive for. The digital vision was then to be deconstructed into smaller progressive steps of social, business and technical capability development that Martinsons should take to ultimately realise the vision.

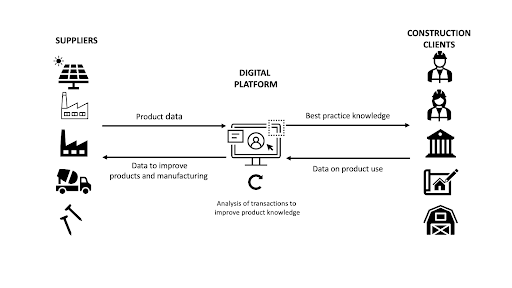

After three weeks, the student groups presented the results of their work for Martinsons. Each group suggested somewhat different visions and pathways for Martinsons, but they also converged on a couple of overarching themes. First, all visions included the use of a digital platform that would infer a shift from Martinsons current closed, singular and unidirectional value chain (figure 1) to a more open, multidimensional and multidirectional ecosystem (figure 2).

Figure 1. The current singular and unidirectional flow of manufacturing, sales and product use at Martinsons

The platformization implied in each vision meant that Martinsons should engage with and gain value out of new actors beyond their current supply chain. In terms of suppliers, it was suggested that Martinsons could partner up with more new CLT and Glulam factories, but also actors such as solar panel producers, metalworkers, 3D wood printing companies and concrete companies and other actors that are likely to provide complementary products or services to Martinsons construction projects. On the client side, it was suggested that Martinsons should engage in deeper partnerships with actors involved in construction projects (e.g. construction companies), but also with other construction and housing stakeholders (e.g. municipalities, engineering consultants and real estate owners).

Figure 2. A vision of Martinsons future manufacturing, sales and product use supported by a digital platform mediating data transactions

The student groups envisioned Martinsons to either become a provider where it develops and maintains the digital platform or a participator where Martinsons joins an emerging digital platform developed and maintained by an external actor. However, regardless of what path Martinsons should choose, the suggested roadmaps focused on the gradual improvement of three capabilities key for Martinsons transformation: operational stability and flexibility, digital innovation capacity, and transformation management.

Operational stability concerns the ability of the underlying operational infrastructure to support efficient and effective processes at Martinsons, and relevant efforts towards improving this ability includes the removal of silos where specific programs, systems and organisational units act in isolation with low interoperability. Conversely, operational flexibility captures the ability of the underlying operational infrastructure to be adjusted to new conditions, which can be improved by aligning it with existing and emerging industry standards for data exchange.

Digital innovation capacity is in this context seen as Martinsons ability to innovate with new digital technology while at the same time being able to effectively exploit its core business. To improve this ability, it is key that Martinsons gains access to digital expertise through training, recruitment or collaboration with external actors (e.g. companies, a digital innovation hub or a university), and that this expertise is integrated with its existing expertise in the wood construction domain. To not disrupt the exploitation of its core business, Martinsons can experiment with, and evaluate, digital initiatives in separated projects that, if successful, are gradually assimilated into the organisation.

Finally, transformation management captures the ability of Martinsons to successfully manage and gain value out of the digital transformation process that platformization implies. A vital first step towards improving this ability is for Martinsons to instate a form of digital unit in the company. The digital unit should consist of key people from senior management, operations, IT and business departments. Its goal is to define and continually redefine the vision for where Martinsons is heading with its digital transformation and to communicate this clearly to the rest of the organisation. Further tasks of the digital unit include strategising tactical moves that bring Martinsons closer to the vision, monitoring transformation progress, and ensuring the successful assimilation of new technologies.

The results of this pilot will serve as a key input for an upcoming project at Martinsons. During the coming year, Martinsons will engage in a project to explore available digital options that can be used to coordinate actors and data streams in its construction projects and connect construction sites with Martinsons internal operations.

Customer benefit

This pilot project has provided Martinsons with several benefits that stems from both the process and actual output of the project. The pilot project has provided Martinsons with an arena to reflect on and receive constructive inputs on its current and future business and the role of digital technology in it. Digital transformation is challenging for any company, but particularly so for incumbent SMEs. Through decades of successful business in a particular area, incumbents have resource allocation structures, operational processes and mindsets geared towards efficiently producing particular products in a particular way. With limited resources, SMEs are often dependent and need to be highly focused on their traditional core business, which leaves limited room to explore digital visions that are truly transformative. By engaging with a public enabler such as a university or a digital innovation hub, incumbent SMEs have the opportunity to work with neutral actors that are not focused on selling a particular product or service, but that can instead take a more holistic perspective focused on the development of capabilities key to digital transformation.

Further, the digital transformation roadmaps produced in this pilot project describe viable change processes through which Martisons can address the challenges they are experiencing and achieve a competitive advantage in relation to entrant wood construction actors as well as steel and concrete companies. As evidenced by other incumbent contexts such as the taxi and hotel industries, it is not a matter of if but when digital platforms will emerge in the construction business. As an incumbent actor, Martinsons needs to decide if it will provide or participate in one and adapt its value creation and capture logic accordingly. Doubtless, becoming a digital platform provider is a high risk project for any incumbent SME, but the potential reward is substantial. As the provider of a widely adopted digital platform mediating the transaction of data in wood construction projects, Martinsons can act as a gatekeeper for the connection between suppliers and clients. Having access to the data transferred between these parties provides the ability to analyse and use it for product and manufacturing improvements.

Competition compared to other solutions

Rather than suggesting specific software, hardware or system, this pilot project has centered on a wider strategic and temporal perspective and focused on the development of capabilities key to successful digital transformation. Indeed, incumbent SMEs in traditional industries often have limited resources and need to remain focused on their core business, and they therefore tend to seek specific digital solutions that can solve specific problems right now. However, without an overarching digital strategy that ties into a long-term digital vision, such isolated digital initiatives have a high risk of resulting in a lack of adoption and assimilation, silo-building, and an overall inability to gain strategic value out of digital technology investments. The digital transformation roadmaps produced in this pilot project triggers Martinsons to take a more strategic and long-term perspective on their digital investments.

The roadmaps produced in this pilot project are centered on platformization, but this is not the only focus that Martinsons can set for its digital transformation. It is highly plausible that digital platforms will come to play a key role in the future construction industry, and that construction companies will be dependent on them for value creation and capture. However, becoming a platform provider can be extremely resource demanding and it represents a significant step away from the linear value creation logic of a traditional industry company. Should Martinsons assess the risks to be too high with a provider approach, it may be more strategically sound to instead remain vigilant for emerging platforms from other providers and ensure that it has the ability to gain value out of them as a participator. Regardless of what end-vision it decides to strive for, operational stability and flexibility, digital innovation capacity, and transformation management represent key capabilities whose improvement would help Martinsons to successfully initiate and maintain its digital transformation.